Changhong Mining Machinery’s Rock Drill Bit is strong and durable

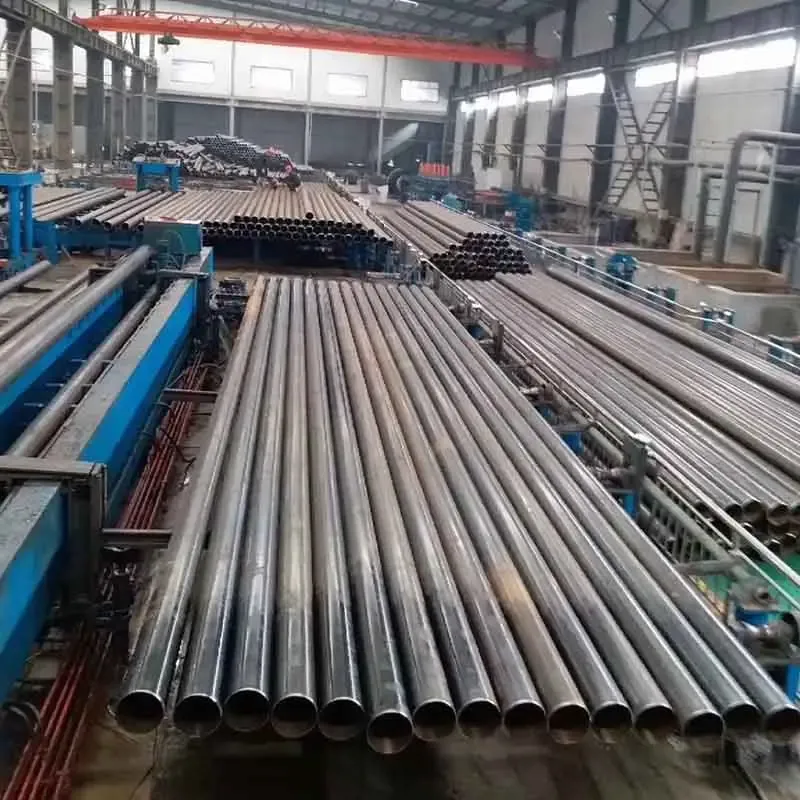

Drilling, also known as boring, is a simple process using specialized tools called rock drill bit.

Hydraulic rock drills are strong equipment to drill through challenging terrains, such as hard rock and other sedimentary strata. Selecting the appropriate drill bit for a rock drill is crucial to ensure optimal drilling performance. Making the right decision also lowers the expense of repairing worn-out and damaged components. Selecting the incorrect drill bit for a rock drill can be costly.

Access to the drilling data of past operations in the vicinity might be beneficial when deciding which bit is ideal for a certain hydraulic rock drills. The risk of shattering or destroying a drill bit while using a rock drills can be decreased by keeping track of which rock drill bits operated successfully in various types of rocks. These data help demonstrate which components worked well for multiple terrains and for removing those that didn’t. This may be yet another practical strategy for lowering drilling project costs.

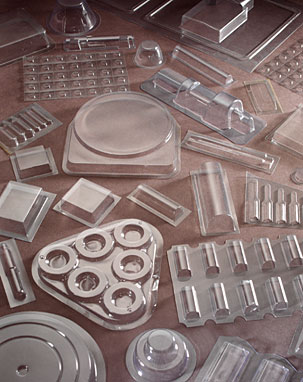

It may be advisable to utilise a PDC bit for tasks. It require a hydraulic rock drills to create a deep hole with a narrow diameter. As opposed to specific other rock drill bit, it does not have moving parts, making it appropriate for this activity. Several bits may be used with a rock drills. Its provide the best results in each situation and function well in a particular setting. Drillers can make an informed choice that will significantly improve the project’s efficiency with research on the various options.

The best rock drilling bit can be determine by knowing the drilling performance and characteristics of each foot drilled with a specific bit. The more details that can learn about particular ground conditions, the lower the cost of rock drills bit throughout a project. Finding the perfect bit will be the most excellent approach to ensure a successful drilling operation because a drill is only as powerful as the bit that punctures the rock.

Get To Know More About Our Products:-

Anchor Drill Bit | Carbide Button Bit | Down The Hole Drilling | Button Bit | Tapered Drill Bit | Button Drill Bit

Business Profiles:-

docker | amazingradio | codeigniter | sketchfab. | goodreads | pastebin

More Information:-educatorpages | atoallinks | strikingly | zupyak