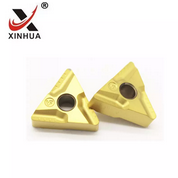

The amount of scrap and component rejects can be reduce by CCMT09T304 by increasing the effectiveness of the current machining setup. A tried-and-true technique for lowering cost per part is to keep your machine running securely with adequate chip management.

There are efficient approaches to get there, such as picking the most advantageous cutting strategy. Using precision coolant, and utilising rapid change solutions.

Utilizing turning grades that provide consistent and predictable tool life can improve the security, efficacy, and productivity of steel turning operations. Additionally, unexpected Tungsten Carbide pauses, carbide insert waste. And work piece material waste can be decrease, which are necessary conditions for sustainable machining. When extended tool lifetimes are combined with increased wear and heat resistance.

Carbide Endmill

There are many things to consider while choosing turning inserts. To maximize metal removal rates, look for a sturdy substrate that resists plastic deformation and a post-treatment that performs well in intermittent cutting processes.

Make that the coating you select also gives a long tool life, improved wear resistance, and reliable and consistent performance.

A lot of continual machine setup optimization is required. But it’s essential to consider new possibilities and learn about cutting-edge technology and methodologies.

For instance, using the all-directional turning strategy can increase Grooving Inserts productivity by more than 50% and lead to substantially faster metal removal rates. Additionally, we provide a variety of cutting tool types based on the specifications for processing materials and machinery.

Keywords-:

APMT1604 | Ball Endmill | Carbide Endmill | CCMT09T304 | End Mill Bits

For More Info-:

Blogger | Professionalsupplierschina | Sites.google