Know about injection moulding lifter and its significance | startmould.com

One of the most time-consuming production procedures available today is injection moulding. It has evolved into a dependable mass manufacturing method through time, consisting of several components that work together to ensure that everything proceeds as intended.

An integral element of the injection moulding system, an injection moulding lifter moves on an angle during the ejection stroke to slide and draw the cavity steel away from the undercuts in the die. Mould core is also an essential component of injection moulding.

The typical lifter is primarily used to produce interior undercuts in moulded plastic components while also providing a means of ejection once the final product, such as plastic-molded chairs or vehicle plastic parts, has been formed. This mechanism has a fundamental design and some degree of stiffness, which enables it to move across a minimal distance.

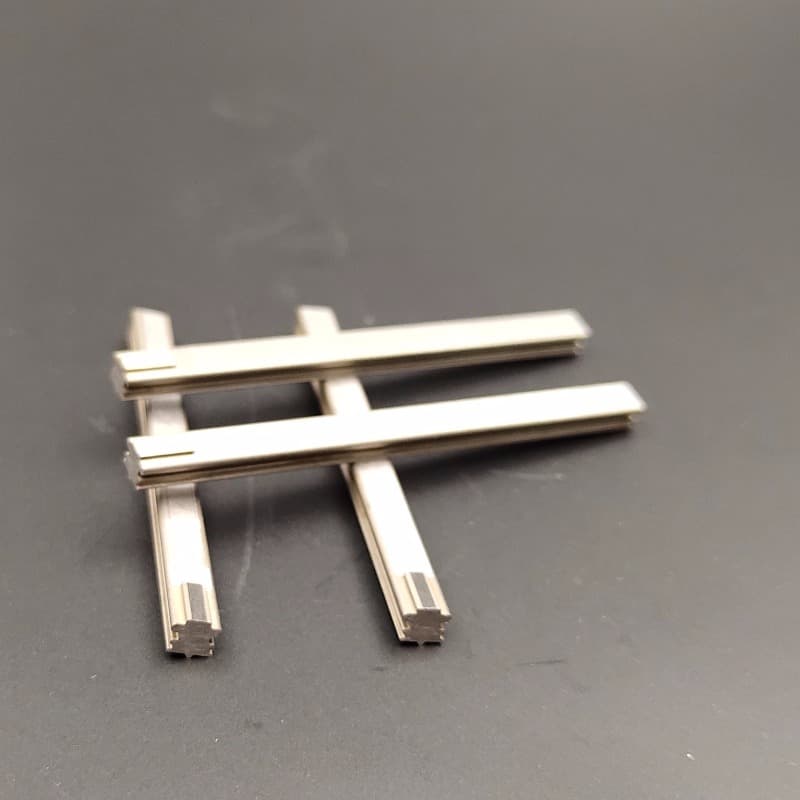

The body and the shaping pieces are the two primary components of the injection moulding lifter. Injection moulding lifters can be categorized as integral or non-integral according to this. The body and the forming components that are a part of the structure define these two differences.

An integral lifter also makes it simple to use a combined form, which helps add replacements and perform maintenance and repairs without affecting the other components of the injection moulding machine. The casting insert is the prime component of the system.

The injection molding technique is improving and more dependable as new pieces are introduced and the ones already there are improved. The use of injection moulding lifters is only the tip of the iceberg; they will continue long into the future.

Keywords :-

Mould core | Mould cavity | Stamping punch | Molded parts | Parting line injection molding | Moulding components | Insert molding | Precision Machined Parts