The Easy Way to Package With Flow Wrap Machine

Can you imagine saving time, money, and energy by running your end-of-line production more efficiently? Yes, we do with packaging machines like, Flow Wrap Machine, Soap Packing Machine, and Flow Wrap Machine.The Easy Way to Package With Flow Wrap Machine.

You wouldn’t believe it if it weren’t true. However, it does exist! Automation at the end of the line comes into play. The goal of end-of-line automation is to ensure that your products are packaged properly and ready for distribution at the end of your production line.

End-of-line automation enables:

Hot glue or sharp tape cutters won’t pose a threat to you

Snowballing fatigue no longer leads to employee mistakes, accidents, and erratic label application throughout a shift

Injuries caused by repeated bending, lifting, and twisting are a thing of the past

There is near-perfect consistency in packing, labeling, and production lines

Packing will go smoothly for you

Spend less time juggling shifts, absences, and lunch breaks for humans

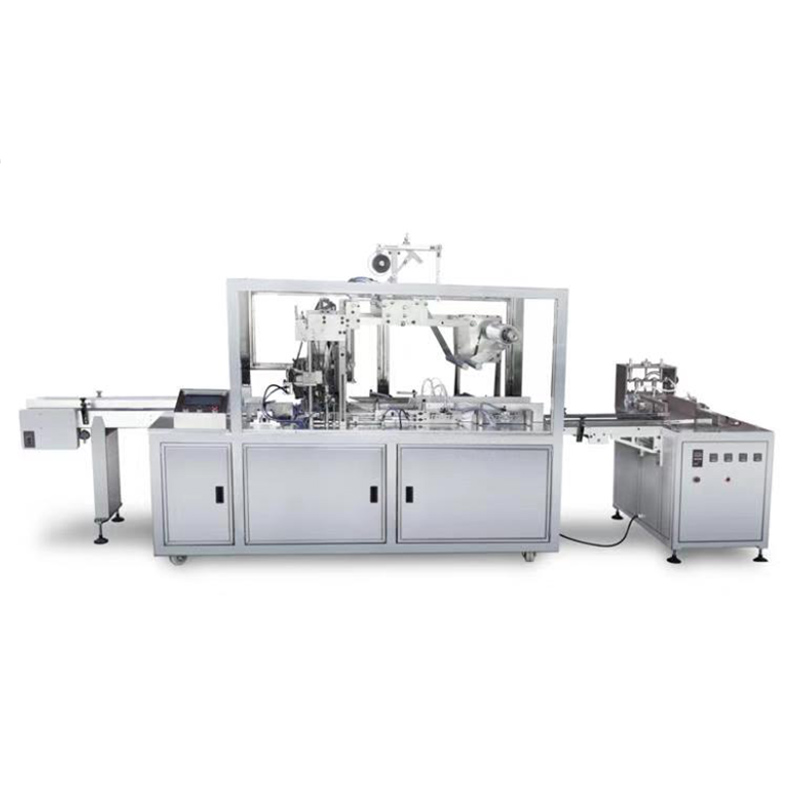

Overwrapping Machine

Your production process becomes more accurate and error-free when you automate it at the end of the line. The benefits of end-of-line automation are very well suit to our many new ways of doing things in a post-pandemic world:

Social distance is unnecessary

The workers don’t touch the products, boxes, or labels

End-of-line production will never stop because machines can’t call in sick.

Keywords: Bottle Washing Machine,Cartoning Machine,Filling and Sealing Machine,Packing Machine,Labeling Machine,Filling Machine,Sealing Machine,Cosmetic Machinery,Bottle Washing Machine,Water Bottle Packing