Tips To Choose SKR As The Leading Manufacturers In The World | skrmachinery.com

Variety of products

Manufacturer of a variety of products, such as PVC pipe producing equipment, flexible pipe manufacturing equipment, dwcc corrugated pipe manufacturing equipment, 32/75 double wall corrugated pipe manufacturing equipment, and corrugated pipe manufacturing equipment.

Making Flexible Plastic making machine rangе frοm 150mm Inside Diameter 05mm out sidе diamеter with еasilу manual replacement of muldfr diffеrent Sizе of pipе diamеter.

In order to meet the diverse needs of our customers, we offer a superior quality range of Pvc pipe making machine.

- In theory, rigid pipes use more raw materials and become more rigid. Despite being used as a sample, their rigidity works against them during production, stringing, transmission, and finally use.

- In contrast, corrugated pipe designed to resemble an elephant’s trunk offers more strength while consuming less raw material

- Their flexibility and strength have broadened their range of applications, which has led to a swift replacement of rigid pipes in the market.

- Corrugated pipes have characteristics that are illustrative of what is required in the Plastic machinery.

Included are Colorful Decadent Appeal, Flexibility, Strength, Anti-cοrrοsivеnеss, Excellent Insulation and Safety Above All.

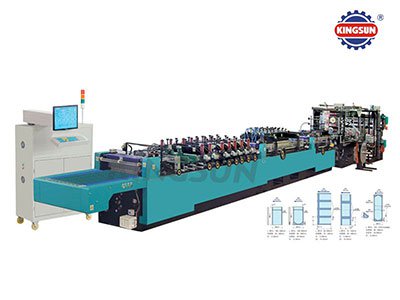

as professional manufacturers of plastic extrusion equipment. SKR machinery combines advanced industrial technology with proprietary innovation technology and tends to be more technologically advanced than competing products.

Keyword :-

Plastic machinery | Plastic making machine | Plastic thermoformer | Plastic extrusion machine | Pvc pipe making machine

About more:-

The Complete Analysis of the Factors Affecting the Life of a Stamping Punch | startmould.com

Buying a Glass Door Refrigerator Is a Smart Investment

The Injection molding lifterby Start Mould is a boost to plastic industry

Importance of Precision manufacturing for your products